[Chapter 5] Section 4

Methods of inspection and maintenance of fall arrest equipment

SeeChapter 2, Section 4 (Please perform equipment upkeep every day.)

For reasons such as busy work schedules and laziness, inspection activities may be omitted, or neglected for many years.

In some cases, this results in a serious industrial accident, and afterward the people involved may express regrets: “If only we had inspected the equipment. We could have quickly found the defective part and prevented the accident”.

Just as inspection of protective equipment and safety equipment is specified as the work of each type of operations chief, the work supervisor must first plan and promote inspection, and then implement and confirm it.

However, it is also important for frontline workers to carry out inspection on their own, without being told by anyone else, and continue their own education and training until they “get a bad feeling if they skip inspection.”

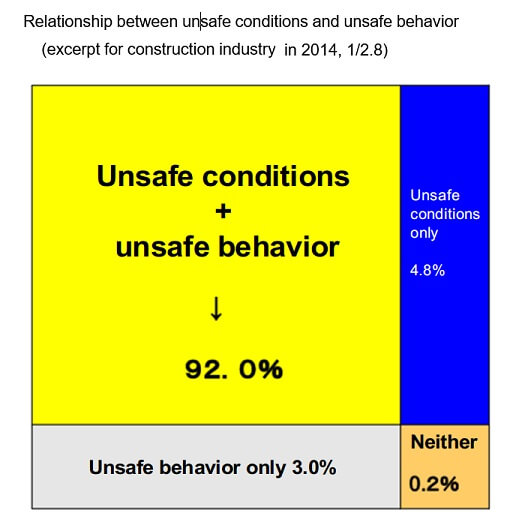

Safety can be improved by reducing “unsafe behavior” and “unsafe conditions” through various safety activities.

I would like you to conduct inspection activities with a good understanding of this point.

受講者様のご希望に合わせ、以下のタイプの講習会もご用意しています

このページをシェアする

講習会をお探しですか?