[Chapter 5] Section 1 ①

1. Inspection before starting work

1. When carrying out work using fall arrest equipment, conduct inspection before starting work in order to prevent danger due to the use of defective products.

Key points of this inspection before starting work are practicing “pointing and calling” and keeping records.

“Pointing and calling” means to say the inspection items out loud, e.g., “Looseness of the helmet chin strap: okay!”

Example of an inspection list

| Inspection item | Result | |

|---|---|---|

| Main rope | Is one span 10 m or less, with a taut rope and no slackening? | |

| Is there any wear, damage, deterioration, deformation, or discoloration, etc.? | ||

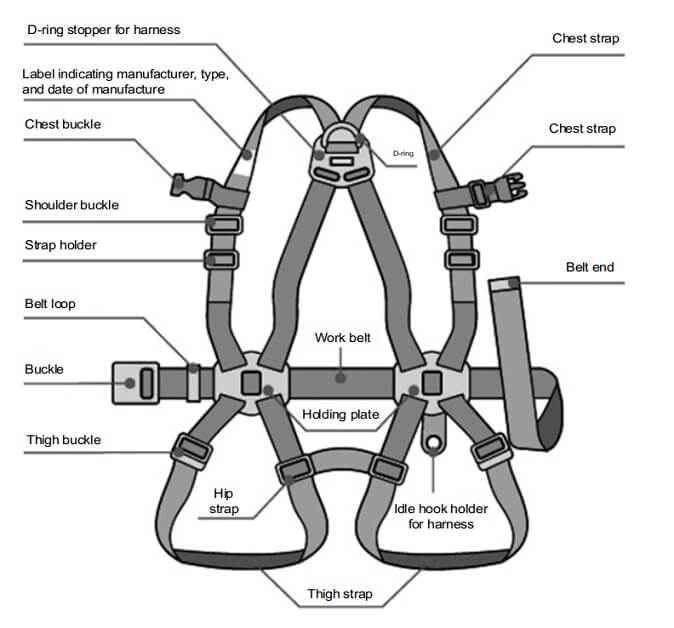

| Fall arrest equipment | Is there any damage, deterioration, or discoloration, etc. of belts/straps? | |

| Is there any damage, deterioration, or deformation of buckles or the D-ring? | ||

| Is there any wear, damage, deterioration, deformation, or discoloration, etc., of the lanyard? | ||

| Is there any damage, deterioration, or deformation of the hook? | ||

| Are any belts or straps loose? | ||

| Is the D-ring positioned slightly above the scapula (shoulder blade)? | ||

| Safety helmet | Are you wearing a safety helmet for fall protection? | |

| Is there any damage, deformation, or deterioration of the helmet? | ||

| Is there any damage to the impact absorbing liner, etc.? | ||

| Is the chin strap securely fastened? | ||

| Safety shoes | Are you wearing the right size shoe? | |

| Are the shoelaces securely fastened? | ||

*Be sure to fill in the “Date started use.

Suggested expiration dates for use ➡

2 years from the start of use for ropes, lanyards, and straps, and 3 years from the start of use for other equipment.

(Voluntary standard of manufacturers and industry groups)

(Voluntary standard of manufacturers and industry groups)

受講者様のご希望に合わせ、以下のタイプの講習会もご用意しています

このページをシェアする

講習会をお探しですか?