[Chapter 4] Section 2 Relevant Clauses in Laws, Ordinances and Safety and Health Regulations④

[Ministerial Ordinance] Ordinance on Industrial Safety and Health②

Article 563 (Work Floor)

(1)The employer must provide a workplace on scaffolding (excluding single-row scaffolding, same as (iii)) having a height of 2 m or higher with a work floor that conform to the following requirements:

(i)the floor materials to have the bending stress calculated in accordance with the distance between fulcrums and the load applied during work that does not exceed the value of allowable bending stress listed in the right column of the following Table in accordance with the type of lumber listed in the left column of the same Table; (Table)

(ii)the width, clearance between floor materials, and clearance between the floor material and standards shall be as follows, excluding hanging scaffoldings;

(a)Width of 40 cm or more.

(b)Clearance between floor materials to be 3 cm or less.

(c)Clearance between floor material and standards shall be less than 12 cm.

(iii)In areas where there is a risk of danger to workers due to falls, the following equipment (limited to equipment of sturdy structure that is not likely to bend and is not significantly damaged, deformed, or corroded) shall be installed in accordance with the following types of scaffolding, respectively. (Hereafter referred to as “fall prevention equipment for scaffoldings”)

(a)Prefabricated scaffolding (Excluding the part pertaining to the gable surface. The same shall apply in (b). ) Any of the following equipment:

(1)cross bracing and rails having a height of 15 cm or more and 40 cm or less, or baseboards having a height of 15 cm or more, or equipment having functions equal to or greater than those of the foregoing.

(2)Handrail frame

(b)Scaffold handrail, etc., and middle rails, etc., other than prefabricated scaffold

(iv)to use brackets, ledgers, girders, trestle or other supporting materials for the work floor having a strength sufficient to bear the load applied; and

(v)to fix the floor boards to two supports or more to prevent displacement or coming off, excluding hanging scaffoldings.

(vi)When it is liable to endanger workers due to falling objects for work, to provide baseboards, mesh sheets or netting with a height of 10 cm or more or equipment having equivalent or higher functions (Hereinafter referred to as “baseboards, etc.”.). Provided, however, that this shall not apply to the case where the facilities installed pursuant to the provision of item (iii) have the same or more functions as the baseboards, etc., or where it is extremely difficult to install the baseboards, etc. due to the nature of the work, or when the baseboards, etc. are temporarily removed due to the necessity of the work, and when an entry area is established.

(2) The provision of (c) of item (ii) of the preceding paragraph shall not apply in the case falling under any of the following items and when falls has taken measures to prevent the dangers to workers such as setting up protective nets at places where the gap between floor material and the standards is 12 cm or more:.

(i)When the sum of the clearances between the standards and both ends of floor material in the direction of girders is less than 24 cm:

(ii)When it is difficult to reduce the total of the clearance between the standards and both ends of floor material in the direction of girders to less than 24 cm due to the nature of the work.

(3)The provision of item (iii) of paragraph (1) of this Article shall not apply to the case where it is extremely difficult to install fall prevention equipment for scaffold due to the nature of the work or the case where fall prevention equipment for scaffold is temporarily removed due to the necessity of the work, when the following measures are taken:.

(i)To provide facilities, etc., for safely installing fall prevention equipment that meet performance requirements, and take measures to have workers use thesefall prevention equipment or measures having equivalent or better effects.

(ii)Not allow workers other than those concerned to enter the place where the measures set forth in the preceding item are taken.

(4)The provisions of item (v) of paragraph (1) shall not apply in any of the following cases:

(i)When boards having a width of 20 cm or more, a thickness of 3.5 cm or more and a length of 3.6 m or more are used as floor material and are moved according to the work, and the following measures are taken:

(a)To hang scaffolding boards over three or more supports.

(b)The length of a projecting part of a scaffolding board from a fulcrum shall be 10 cm or more, and 1/18 or less of the length of scaffolding board except in the case where it is unlikely that workers will put their feet on the said projecting part.

(c)When stacking scaffolding boards in the longitudinal direction, they shall be stacked on a fulcrum, and the length of the stacked portion shall be 20 cm or more.

(ii)When boards having a width of 30 cm or more, a thickness of 6 cm or more and a length of 4 m or more are used as floor material and the measures prescribed in (b) and (c) of the preceding item are taken.

(5)The employer shall, when having temporarily removed fall prevention facilities for scaffold for the necessity of work pursuant to the provision of paragraph (3), immediately restore the said facilities to their original state as soon as it is no longer necessary.

(6)A worker shall, when having been instructed to use fall prevention equipment that meet requirements in the case set forth in paragraph (3), use it.

[Interpretation example] The term “work area at a height of two meters or more on scaffolding (excluding single-sided scaffolding)” in Paragraph (1) of this provision means a place where the height from the ground or floor to the work area is two meters or more, regardless of the structural height of the scaffold.

Article 564 (Assembling of Scaffoldings)

(1)When carrying out the work set forth in Article 6, item (xv) of the Order, the employer must take the following measures:

(i)to make the timing, scope and procedures of assembling, dismantling or altering known to the workers engaging in the work;

(ii)to prohibit workers other than those concerned from entering the area where assembling, dismantling or altering work is to be carried out;

(iii)to suspend the work when dangers due to bad weather conditions such as strong wind, heavy rain, or heavy snow is expected;

(iv)when carrying out the work of fastening, removing or handing over materials for scaffoldings, to provide scaffolding boards having a width of 20 cm or more, and take measures such as having workers use safety belts in order to prevent the danger to workers due to falling; and

(a)To provide a work floor having a width of 40 cm or more. Provided, however, that this shall not apply when it is difficult to install said work floor.

(b)To provide equipment, etc., for safely installing performance demand fall prevention equipment and take measures to have workers use performance demand fall prevention equipment. Provided, however, that this shall not apply when measures having effects equivalent to or greater than said measures are taken.

(v)To have workers use lifting ropes, lifting bags, etc., when lifting or lowering materials, instruments, tools, etc. However, this shall not apply to the case where it is unlikely to endanger workers due to falling objects.

(2)The workers, in carrying out the work set forth in item (iv) of the preceding paragraph, when having been instructed to use safety belts, etc., must use them.

Article 565 (Appointment of an Operations Chief of Assembling of Scaffolding)

As regards the work set forth in Article 6, item (xv) of the Order, the employer must appoint an operations chief of assembling of scaffolding from those who have completed the skill training course for operations chief of assembling of scaffolding

Article 566 (Duties of the Operations Chief of Assembling of Scaffolding)

The employer must have the operations chief of assembling of scaffolding carry out the following matters;provided, however, that the provisions of item (i) do not apply to the work of dismantling:

(i)to check for defects in materials, and remove those defective;

(ii)to inspect the function of instruments, tools, safety belts, etc., and safety helmets, and remove those defective;

(iii)to decide the work method and the placement of workers, and supervise the progress of work; and

(iv)to monitor the use of safety belts, etc., and safety helmets

Article 567 (Inspection)

(1)When a worker performs work on scaffolding (excluding suspended scaffolding), he/she shall inspect the scaffolding for any removal or detachment of the fall prevention equipment installed at the work area before starting the work on that day, and shall immediately repair any abnormalities found.

(2)When carrying out the work on scaffoldings after bad weather conditions such as strong wind, heavy rain, heavy snow, a moderate or greater earthquake, or assembling, partially dismantling or altering scaffoldings, the employer must inspect the following matters before commencing the work, and when having found any abnormality, immediately make repairs:

(i)condition of damage, mounting and placing of floor materials;

(ii)condition of loosening at the fastening, connecting and mounting parts of standards, ledgers, brackets, etc.;

(iii)condition of damage and corrosion of clamping materials and clamps;

(iv)existence of removal and coming off of fall prevention equipment, etc.;

(v)attached state of baseboards and whether they have dislocated

(vi)condition of subsidence and sliding of leg parts;

(vii)condition of mounting and existence of removal of diagonal bracings, stays, ties to wall and other reinforcement materials;

(viii)existence of damage of standards, ledgers and brackets; and

(ix)condition of the mounting part of projected girders and lifting cables, and the function of lifting devices

(3)The employer shall, when having carried out the checkup set forth in the preceding paragraph, record the following matters and preserve them until the completion of the work using scaffold:

(i)result of the inspection

(ii)In the case where measures such as repair, etc. have been taken based on the results set forth in the preceding item, the details of said measures

Article 568 (Inspection of Hanging Scaffolding)

When carrying out the work on hanging scaffolding, the employer must inspect the matters listed in items 2 (i) through (iv), items (vii) and (ix) of the preceding article before commencing the work for the day, and when having found any abnormality, immediately make repairs.

Article 569 (Log Scaffoldings)

(1)The employer shall, as regards a log scaffold, not use unless otherwise prescribed as follows:

(i)to have the interval between standards 2.5 m or less, and provide the first ledger over the ground at a place having a height of 3 m or less;

(ii)for the leg part of standards, to take measures such as embedding the foot of standards underground, providing bridge batten of foot posts, and using sills in order to prevent standards from sliding or settling;

(iii)when the couplings of standards are lap joints, to band the joining parts at two locations or more with overlapping of 1 m or more; when the couplings of standards are butt joints, to construct the standards with two logs, or band the joining part at four locations or more with a splint having a length of 1.8 m or more;

(iv)for the joining parts and crossing parts of standards, ledgers, brackets, etc., to be firmly bound with wires or other strong materials;

(v)to reinforce log scaffoldings using diagonal bracing;

(vi)for single row scaffolding, double row scaffolding or cantilever scaffolding, to provide ties to wall or stays that conform to the following requirements:

(a)the interval to be of 5.5 m or more in the vertical direction and 7.5 m or more in the horizontal direction;

(b)to make the scaffolding solid with steel pipes, logs, etc.; and

(c)when the scaffoldings are composed of tension components and compression components, the interval between these components are to be within 1 m.

(2)The provisions of item (i) of the preceding paragraph do not apply to the case where it is difficult to conform to the requirements of the provisions of the item due to the necessity of the work and the parts are reinforced with bent ledgers, two logs combined, etc.

(3)The provisions of paragraph (1), item (vi) do not apply when ties to wall or stays are removed for the work of mounting of window frames and finishing of walls, or it is unavoidable due to necessity of the work, when taking measures in order to prevent the scaffoldings from collapsing, such as providing diagonal components to standards or ledgers in lieu of the ties to wall or stays.

Article 570 (Steel Pipe Scaffoldings)

As regards steel pipe scaffoldings, the employer must not use them unless they conform to the following requirements:

(i)for the leg part of the scaffoldings (excluding movable scaffoldings with casters), to take measures such as providing the bridge batten of foot posts with base fittings, and plankings, square timbers, etc., in order to prevent the scaffolding from sliding or subsiding;

(ii)for movable scaffolding with casters, to take measures such as securely fixing the casters with a brake, or other brakes, pawl, etc. or fastening a part of the scaffolding to a solid building, in order to prevent scaffoldings from moving unexpectedly;

(iii)to securely join or fasten the joining parts or crossing parts of steel pipes with suitable fittings;

(iv)to reinforce the scaffolding with bracings;

(v)for single row scaffolding, double row scaffolding or cantilever scaffolding, to provide ties to wall or stays that conform to the following requirement:

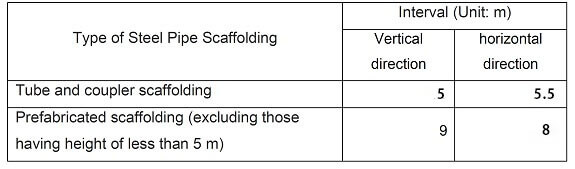

(a)the interval to be the value equal to or less than those listed in the right column of the following Table in accordance with the type of steel pipe scaffolding listed in the left column of the same Table;

(b)to make the scaffolding strong with materials such as steel pipes and logs;

(c)when the scaffoldings are composed of tension components and compression components, the interval between these components are to be within 1 m; and

(vi)when a scaffolding is to be installed in the vicinity of an overhead power line, to take measures to prevent contact with the overhead power line such as moving the overhead power line or installing protecting equipment for insulating.

(2)The provisions of paragraph (3) of the preceding Article apply mutatis mutandis to item (v) of the preceding paragraph.In this case, the term “paragraph (1), item (vi)” in paragraph (3) of the preceding Article is deemed to be replaced with ” Article 570, paragraph (1), item (v)”.

Article 571 (Steel Pipe Scaffolding Conforming to the Steel Pipe Standards)

As regards the steel pipe scaffoldings composed of steel pipes that confirm to the steel pipe standards, the employer must not use them unless they conform to the requirements set forth in the following items (i) through (iv) for single-pipe scaffoldings and in items (v) through (vii) for prefabricated scaffoldings, in addition to the requirements set forth in paragraph (1) of the preceding Article:

(i)the intervals of the standards are to be of 1.85 m or less in the direction of the crossbeam and 1.5 m or less in the direction of the beam;

(ii)to provide the first ledger above the ground at the height of 2 m or lower;

(iii)the standards exceeding 31 m measured from the highest point of the standards to consist of the combination of two steel pipes;

(iv)to limit the loading capacity between the standards to 400 kg;

(v)to provide the horizontal components at the top level and for each fifth level or less;

(vi)to take measures to prevent the beam frames and bracket frames from moving laterally with horizontal bracings; and

(vii)when the scaffolding has a height exceeding 20 m, and when the work involves carrying heavy materials, the main frame is to be the height of 2 m or less, and the interval is to be 1.85 m or less.

(2)The provisions of item (i) or item (iv) of the preceding paragraph do not apply when it is difficult to comply with the provisions due to necessity of work and when the employer takes the measures prescribed in the following Article for the value of the maximum bending moment obtained by the calculation supposing that the components between each fulcrum as a simple beam structure.

(3)The provisions of paragraph (1), item (ii) do not apply when it is difficult to comply with the provisions due to the necessity of work and when the parts are reinforced with two steel pipes combined, etc.

Ordinance on Industrial Safety and Health Part IV, Special Regulations Part I, Special Regulations Concerning Principal Employers

Article 654 (Measures Concerning a Temporary Passage)

In the case set forth in Article 31, paragraph (1) of the Act, when the orderer has workers of the contractor use a temporary passage, the orderer must ensure that the temporary passage complies with the standards of temporary passages prescribed in Article 552.

Article 655 (Measures Concerning Scaffoldings)

In the case set forth in Article 31, paragraph (1) of the Act, when the orderer has the workers of the contractor use scaffoldings, the orderer must take the following measures concerning the scaffoldings:

(i)to set the maximum loading capacity of the work floor in accordance with the structure and material used, and to display the capacity at a readily visible place of the scaffolding;

(ii)to inspect the following matters after bad weather conditions such as strong wind, heavy rain and heavy snow, or a moderate or greater earthquake, before commencing the work on the scaffoldings, and to promptly make repairs when there is risk of endangering workers:

(a)condition of damage, mounting and placing of floor materials;

(b)condition of loosening of the fastening, connecting and mounting parts of standards, ledgers, brackets, etc.;

(c)condition of damage and corrosion of clamping materials and clamps;

(d)existence of coming off of handrails, etc.;

(e)attached state of baseboards and whether they have dislocated;

(f)condition of settling and sliding of leg parts;

(g)condition of mounting of bracings, stays, ties to the wall and other reinforcement materials;

(h)damage of standards, ledgers and brackets; and

(i)condition of the mounting part of projected girders and lifting cables and the function of lifting devices;

(iii)beyond what is set forth in the preceding two items, to ensure that the scaffoldings comply with the standards specified by the Minister of Health, Labour and Welfare pursuant to the provisions of Article 42 of the Act and the standards of scaffoldings prescribed in Part II, Chapter X, Section 2 (limited to Articles 559 through 561, Article 562, paragraph (2), Article 563, Articles 569 through 572, and Article 574.

(2)The orderer shall, when having carried out the check set forth in item (ii) of the preceding paragraph, record the following matters and preserve them until the completion of the work using scaffold:

(i)result of the inspection

(ii)In the case where measures for repair, etc. have been taken based on the results set forth in the preceding item, the details of said measures.

Article 655-2 (Measures concerning work platform)

(1)In the case set forth in Article 31, paragraph (1) of the Act, when the orderer has the workers of the contractor use work platforms, the orderer must take the following measures concerning the work platforms used:

(i)to set the maximum loading capacity of the work platform in accordance with the structure and material used and to display the capacity at a readily visible place of the work platform;

(ii)to inspect the following matters after bad weather conditions such as strong wind, heavy rain and heavy snow, or a moderate or greater earthquake, before commencing the work on the work platform, and promptly make repairs when there is a risk of endangering workers:

(a)condition of sliding and subsidence of supports;

(b)condition of damage of supports, girders, etc.;

(c)condition of damage, mounting and placing of floor materials;

(d)condition of loosening of the fastening, connecting and mounting parts of supports, girders, diagonal bracings, etc.;

(e)condition of damage and corrosion of clamping materials and clamps;

(f)condition of mounting and removal of horizontal collar braces, diagonal bracings and other reinforcement materials; and

(g)whether the handrails, etc., have been removed or have come off;

(iii)beyond what is set forth in the preceding two items, the work platform must comply with the standards of work platforms prescribed in Part II, Chapter XI (limited to Article 575-2, Article 575-3 and Article 575-6)

(2) The orderer shall, when having carried out the check set forth in item (ii) of the preceding paragraph, record the following matters and preserve them until the completion of the work using the work floor.

(i)result of the inspection

(ii)In the case where measures for repair, etc. have been taken based on the results set forth in the preceding item, the details of said measures.

地域・講習・人数に合わせてすぐに予約可能

講習会を予約する受講者様のご希望に合わせ、以下のタイプの講習会もご用意しています

このページをシェアする

講習会をお探しですか?