[Chapter 2] Section 1 Cranes and other lifting equipment

1 Climbing jib cranes (tower cranes)

As construction progresses, the mast is added as needed, and the jib crane is equipped with a climbing device that raises the slewing body and performs hoisting, lowering, and turning motions.

These cranes are used in the construction of skyscrapers and large structures, as well as in the pouring of concrete for dam construction.

When one construction project is completed, the crane is dismantled and relocated to another construction site.

2 Mobile cranes (rough terrain cranes)

Rough terrain cranes, which are included in wheel cranes, feature a unique steering mechanism (steering mechanism) and are equipped with large tires and all-wheel drive, enabling them to travel on uneven terrain and relatively soft ground.

They are also highly maneuverable in confined areas thanks to the four types of steering mechanisms provided.

3 Loading type truck cranes

(1) Loading type truck cranes are mounted between the bed and the cab of a truck, and the crane is operated by drawing power from the engine for driving the truck.

Many of these cranes have lifting capacities of less than 3 tons. In addition, many are known to tip over, thus requiring reliable measures to prevent this.

[Measures to prevent overturning]

(1) Stretch out the outrigger to the maximum

(2) Use steel plates or other means to prevent sinking under the outrigger

(3) Do not make sharp turns.

(4) Work with the boom erected as much as possible, even in the rear.

(5) Do not pull the load.

4 Crane related qualifications

| Floor-operated type with a lifting load of 5 t or more | Skill training course for operation of floor-operated crane |

| Lifting load of less than 5 t | Special training for operating cranes |

| Lifting load of 5 t or more | Mobile crane driver’s license |

| Lifting load 1 t to less than 5 t | Skill training course for small-sized mobile cranes |

| Lifting load of less than 1 t | Special training for operating mobile cranes |

| Cranes with lifting capacity of 1 ton or more Mobile cranes with a lifting capacity of 1 ton or more |

Skill training course in slinging operations |

| Cranes with lifting capacity of less than 1 ton Mobile cranes with a lifting capacity of less than 1 ton |

Special training for slinging operations |

Safety Regulations for Cranes, etc. (Exclusion from Application)

Article 2

This Ministerial Ordinance shall not be applied to cranes, mobile cranes, derricks, elevators, construction lifts or simple lifts listed in the following item.

(i) Cranes, mobile cranes or derricks with a lifting load of less than 0.5 tons

5 Knowledge of cranes, etc.

1.Lifting load: Means the maximum lifting load. Generally indicates the capacity of the crane.

2.Rated load means the load which may actually be lifted.

3.When lifting a load using a crane equipped with a device to prevent the detachment of the wire rope for slinging from the hook (hereafter referred to as a ” detachment stopper device ” ), the detachment stopper device must be used.

4.Workers shall not be allowed to enter under lifted loads in the following cases:.

(a)When lifting a load slung with a hacker.

(b) When lifting a load slung with a single sling clamp.

(c) When suspending loads slung by a wire rope, suspension chain, fiber rope, or fiber belt, etc., at a single point.

(d) When lifting multiple loads at once and they are not secured by being tied together, boxed, or otherwise.

(e) When performing work with a crane, the operator shall establish certain signals to be used in operating the crane, designate a person to give the signals, and have that person give the signals. However, this shall not apply when the crane operator is working alone. Designated persons shall give the specified signals when engaging in the work. Workers engaged in the work shall follow these signals.

For prefabricated scaffolding, single-pipe scaffolding, and log scaffolding on rooftops, etc., heavy lifting equipment such as cranes are used to unload and load the materials to be used. The cranes used in this process must be operated by qualified personnel, and measures required by law must be taken.

In addition, qualified persons are responsible for hanging and removal of the sling. (Exceptions are made for assistants.)

Slinging is the work of hanging and unloading a suspended load using suspension equipment. In other words, when a crane, etc. is used to perform load handling and transportation work, it refers to the preparation, lifting of the load, movement of the suspended load, and placing the suspended load in position by using a wire rope for slinging the suspended load with the hook of the crane, etc.

6 Slinging operations

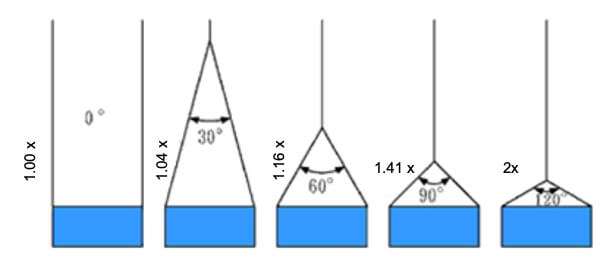

(1) The relationship between the angle of suspension and wire rope tension increases with the angle of suspension, even if the mass of the suspended load is the same. When a load of 2 tons is lifted vertically by two wire ropes, each wire rope exerts 1 ton of tension, but when the wire ropes are angled at 60°, each wire rope exerts 1.16 tons of tension.

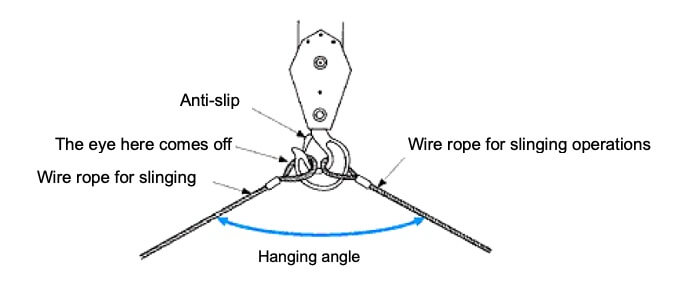

(2) If the suspension angle is too large, the eye of the wire rope for the sling may come off the hook. For this reason, the suspension angle should be within 60 degrees.

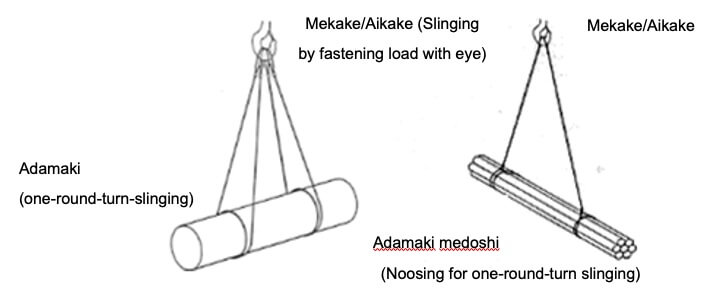

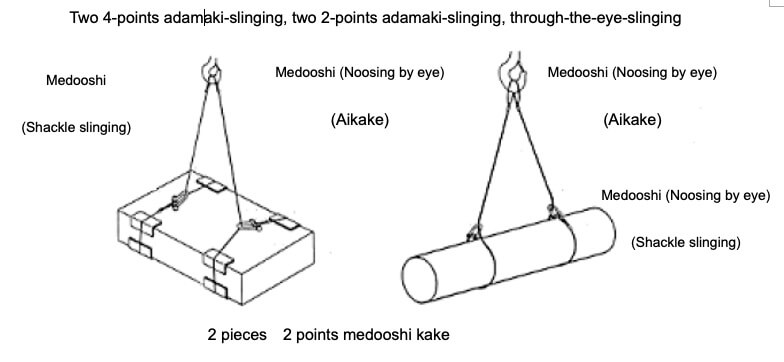

(3) Adamak-slinging (one-round-turn-slinging: a method of winding a wire rope around a load once)

Advantage:

Most effective for preventing the wire rope from slipping as it is pulled by the angle of suspension, especially for long objects.

Disadvantage:

The wire rope needs to be passed under the suspended load twice. (The same applies when removing it).

Caution:

Need to make sure that the wire ropes do not overlap. For steel bars, both ends of the wire rope must be tied tightly with wire before lifting.

Two 4-points adamaki-slinging, two 2-points adamaki-slinging, through-the-eye-slinging

(4)Medooshi (a method of hanging a suspended load by passing the eye of the wire rope through the eye of the opposite side or a double-folded section, so that the load is squeezed while hanging

Advantage:

The frictional force increases as the load is squeezed, preventing slippage between the suspended load and the wire rope. Longer items and multiple items can be grouped together.

Disadvantage:

The strength at the narrowing intersection is lower. The rope is damaged at the point where the rope is tightened, which is not favorable for single- suspension because the load rotates.

Caution:

When tensioning a double-folded rope, it is better to tighten the rope at the eye, so that the strength is not reduced and the tension is equalized. When suspending a load at two points, consider the direction of drawing depending on the load to be suspended. The load may rotate or twist.When using a shackle at the point of the draw, do not use the pin side at the drawn part.

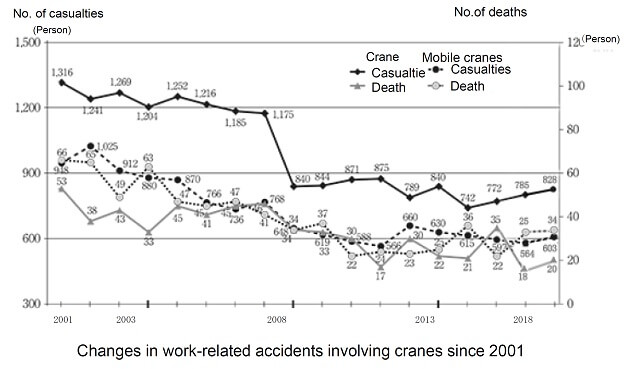

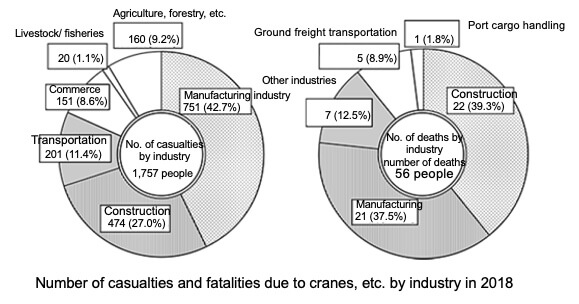

7 Number of crane related accidents (Source: Japan Crane Association (JCA))

(1)Breakdown of 56 fatal accidents caused by cranes, etc.

1. Mobile cranes 34 (60.7%)

2. Cranes 20 (35.7%)

3. Elevators 1 (1.80%)

4. Easy lifts 1 (1.80%)

地域・講習・人数に合わせてすぐに予約可能

講習会を予約する受講者様のご希望に合わせ、以下のタイプの講習会もご用意しています

このページをシェアする

講習会をお探しですか?