[Chapter 1] Section 2 Scaffolding Material, Structure, and Assembly Drawing⑥

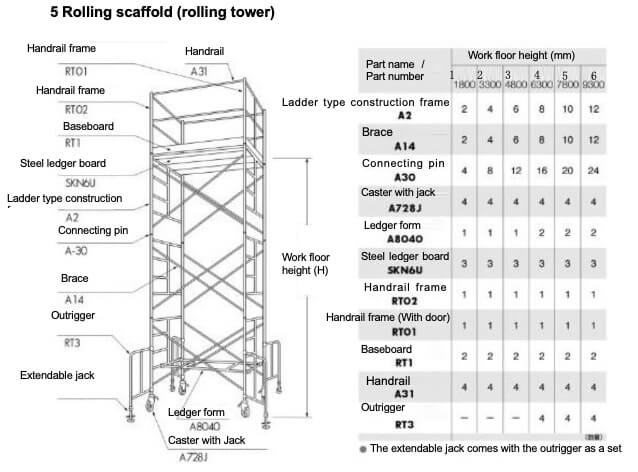

6 Rolling scaffold (rolling tower)

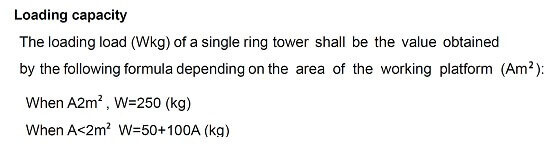

(1)Work floor shall be one of the following:

1.Floor material and girders combined together (hereafter referred to as “floor ledger form”).

2.Scaffold boards used as floor material

(2)The frame structure section consists of the following components (1) to (5). In this case, (6) or (7) are included as a component if deemed necessary.

(1) Construction frame

(2) Diagonal braces or alternative joints

(3) Construction frame joints

(4) Horizontal cross bracing or alternative joint joints

(5) Ledger frame or floor ledger form

(6) Extendable frame

(7) Antechamber

(3)Any of the following types of lifting equipment shall be provided, except when the frame structure is composed of a frame that meets the requirements for a ladder as described in 1. below.

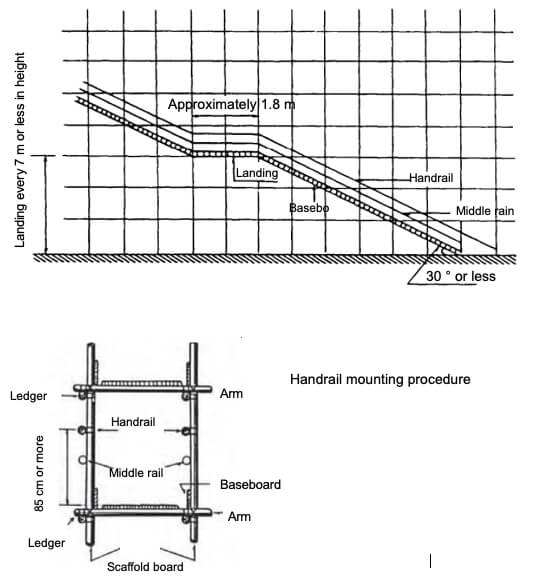

1.Ladder having a step length of 30 cm or more and a step length of 40 cm or less provided at equal intervals

2.Stairs with a gradient of not more than 50 degrees and a width of not less than 40 cm

(4)Around the work floor, there must be a sturdy handrail at least 90 cm high with a middle rail in the middle and a baseboard at least 10 cm high. However, if a sturdy wire netting is provided between the handrail and the work floor, the middle rail and baseboard may be omitted.

(5)Assembly

1.Securely connect connecting parts of the frame so that they cannot be easily detached during use.

2.Indicate the maximum loading capacity in a readily visible location on the rolling scaffold.

3.When using two or more rolling scaffolding by connecting them, connect them securely using steel pipes and clamps, etc.

4.When moving a rolling scaffold, check the condition of the road surface in advance to prevent it from tipping over due to bumps on the road, obstacles, etc.

5.Move rolling scaffolding only after all the landing gear wheel brakes have been released.

6.Workers must not ride on rolling scaffolding.

7.When moving rolling scaffolding, no workers other than the workers concerned shall be allowed to enter the area where there is a risk of danger due to falls, etc.

8.Take the following measures when moving rolling scaffolding that have a stairwell.

・Raise all jacks on the stay.

・Even if the rolling scaffold conforms to the above requirements, if there is a risk of tipping over, it should be reassembled to a height where there is no risk of tipping over, or otherwise prevented from tipping over.

・If there is a risk that the stay may interfere with construction, equipment, etc., remove or fold it.

9.When moving rolling scaffolding that have been provided with wall ties or stays, take measures to prevent them from tipping over, such as by reassembling them at a height that prevents the possibility of them tipping over, removing the sheets, etc.

(6)Fixing in stationary state

1.For the purpose of performing work in a comfortable posture, fix rolling scaffolding in close proximity to the work area (i.e., keep them in a ready-to-use condition at the work area). The same shall apply hereafter).

2.Always operate the brakes on the leg wheels, except when moving. When operating the brakes, the operator shall check the effectiveness of the brakes.

3.When using rolling scaffolding on an uneven or sloped surface, use a jack or similar device to keep the work floor level.

4.When fixing a rolling scaffold with a stay, ensure that there is no abnormality in the condition of the stay’s attachment, grounding, etc.

5.If the rolling scaffold is likely to be subjected to strong wind pressure because of the sheeting on it, etc., provide wall ties or a stay on the rolling scaffold.

6.When installing rolling scaffolding in close proximity to overhead power lines, take measures to prevent contact with the overhead power lines, such as relocating the overhead power lines and attaching insulating protective devices to the overhead power lines.

(7)Loading capacity

1.Do not apply a load in excess of the maximum loading capacity to rolling scaffolding.

2.When loading materials on the rolling scaffold, make sure that they are not eccentric to prevent them from tipping over.

3.Do not use moving ladders, stepladders, etc. on running scaffolding.

4.When removing a handrail, middle rail, etc., for the purpose of working or climbing, return it to its original state immediately after it is no longer necessary.

5.For rolling mobile scaffolding that use the outer space of the framed structure as an ascent path, no more than two persons should ascend or descend from the same surface at the same time to prevent tipping over.

* The height from the bottom of the foot wheel to the work floor and the distance between the spindles of the foot wheels forming the outer edge of the rolling scaffolding shall be determined by the following equation: However, this shall not apply if the rolling scaffold is equipped with wall joints or stays. H≦7.7L-5

In this formula, H and L shall represent the following values, respectively.

H Height from the bottom of the foot wheel to the work floor (unit: m)

L Spindle spacing of foot wheels (unit m)

7 Other scaffolding, etc.

(1)Provide scaffold boards of 20 cm or more in width for tensioning, removing, delivering, etc. of scaffolding materials, and have workers use fall prevention equipment.

(2)When lifting and lowering materials, equipment, tools, etc., workers must use lifting ropes, bags, etc.

(3)The maximum loading capacity shall be specified and made known to the workers.

(4)The scope and order of dismantling and removal must be made known to the workers concerned.

Climbing pier

地域・講習・人数に合わせてすぐに予約可能

講習会を予約する受講者様のご希望に合わせ、以下のタイプの講習会もご用意しています

このページをシェアする

講習会をお探しですか?